What mechanism does the circular knitting machine include

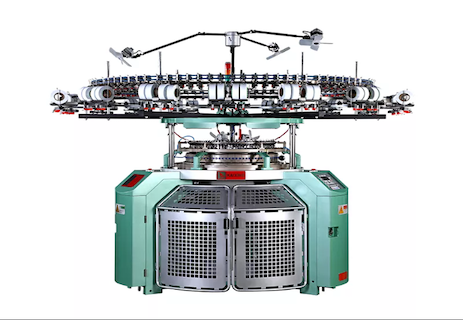

2022-08-31 22:00The circular knitting machine is mainly composed of yarn feeding mechanism, weaving mechanism, pulling and coiling mechanism, transmission mechanism, lubrication and cleaning mechanism, electrical control mechanism, frame part and other auxiliary devices.

01 Yarn institutions

The yarn feeding mechanism, also known as the yarn feeding mechanism, includes the yarn frame, the yarn feeder, the yarn guide, and the yarn ring bracket. Among them, the yarn-feeder is currently recognized as the best in the industry by Merminger Ayrault of Germany (as shown in Figure 1).

Requirements for yarn mechanism:

1.1 The yarn feeding mechanism must ensure that the amount of yarn and tension are uniform and continuous, so as to keep the size and shape of the woven fabric coils consistent, so as to get smooth and beautiful knitted fabric.

1.2 The yarn feeding mechanism should keep the yarn feeding tension reasonable, so as to reduce the needle leakage and weave defects on the cloth surface.

1.3 The yarn ratio of each weaving system should be consistent. The amount of yarn given should be adjustable to meet the needs of changing products.

1.4 The yarn feeder should make the yarn neat and the tension more uniform to effectively prevent yarn breaking.

02 Weaving institutions

Knitting mechanism is the heart of the circular knitting machine, mainly composed of needle, needle, triangle, triangle seat (including needle and sedimentation of the triangle and triangle seat), sedimentation piece (commonly known as Sinker piece, ink piece) and so on.

03 Pull coiling machine

The function of the pull coiling machine is to pull the knitted fabric from the knitting area and wind it into a certain coiling form. It includes drawing roll, cloth roll, spreading frame (also known as cloth support), transmission arm, adjusting gear box. Its characteristics are:

3.1 An induction switch is installed at the bottom of the large plate. When a transmission arm equipped with cylindrical nails passes through, a signal will be generated to determine the number of rolls and revolutions.

3.2 Set the revolution of each piece of cloth on the control operating board. When the machine revolution reaches the set value, it will automatically stop, so that the weight error of each piece of cloth can be controlled within, which is conducive to the cylinder allocation during post-dyeing treatment.

3.3 The setting of the rotation of the rolling fabric frame can be subdivided into 120 or 176 sections, which can adapt to the rolling requirements of various knitted fabrics in a wide range and accurately.

04 Transmission mechanism

The variable speed motor (motor) is controlled by the frequency converter, and then the motor drives the drive shaft gear, which is transferred to the large plate gear, so as to drive the needle cylinder. The driving shaft is straightened to the circular knitting machine , and then drives the yarn feeding mechanism.

05 Lubricating cleaning mechanism

Circular knitting machine is a high speed and precision system cooperate with each other, because the yarn in weaving process will cause a lot of fly (cotton), make it easy to complete weaving center parts because fly, dust and oil pollution caused by poor movement, serious damage to the equipment, so the moving parts of lubrication, dust removal is very important. At present, the lubrication and dust removal system of the great circle machine has fuel injector, radar fan, oil circuit accessories, oil leakage tank and other parts.

Lubrication cleaning mechanism is characterized by:

A. The special oil mist injector provides good lubrication for the surface of braided parts, and the oil surface indication and fuel consumption can be seen intuitively. When the oil in the injector is insufficient, it will automatically stop and warn.

B. The new electronic automatic refueling machine makes the setting and operation more convenient and intuitive.

C. The radar fan has a wide cleaning surface, which can remove flying flowers from the yarn storage device to the weaving part in a wide range to avoid yarn supply obstruction caused by flying flowers.

06 Control mechanism

The control mechanism is used to complete the setting of operation parameters, simple button operation, fault self-stop and indication. It mainly includes frequency converter, control panel (also known as operating board), electrical control box, fault detection equipment, electrical wiring and so on.

07 Frame part

The frame part includes three feet (also known as lower feet), straight feet (also known as upper feet), large plate, three forks, protection door, yarn frame seat. The rack must be secure and secure.